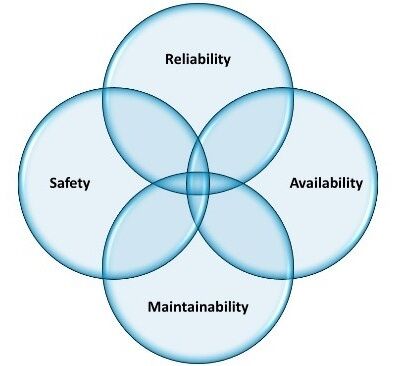

Reliability, Availability, Maintainability, Safety, RAMS for Automotive, Railways, Aerospace, Defence and Industrial

At VerveTronics we work with your team to identify all progressive Reliability Safety and System Management requirements, and perform the activities to ensure that the system will meet stringent Reliability, Availability, Maintainability and Safety requirements. We at VerveTronics, help organizations to effectively integrate customer requirements in line with the relevant International standards: EN 50126, EN 50128, EN50129, EN50121. , IEC 60571, IEC61850, IEC61508. We help out client to achieve technical performance along with the operational performance by effectively managing RAM and Safety activities across the project lifecycle. We carryout RAM & Safety studies using industry accepted standard and tools. Our clients are benefited to save cost and time, reduce risks, increase efficiency, and maximise sustainable outcomes with our highly skilled and motivated project teams.

Failures, recalls, repair time increases severely impact companies bottom line Maintenance and asset management is important to optimise the maintenance duration and cost. VerveTronics Experienced Reliability Engineers work with the customers to maximise the system availability, reduce the operational cost, maintenance cost and duration. VerveTronics follows all the international Safety, RCM and Asset management standards.

RAM Assurance Services

- RAM Assurance Plan

- RAM Analysis Report

- Subsystem Breakdown Structure

- Subsystem Breakdown Structure

- RBD Analysis

- FMEA/FMECA/ FTA Analysis

- RCIL Analysis

- RAM Demonstration Plan

- Asset Maintenance Strategy

- Recommended Spare Parts & Special Tool

- RAM Demonstration Report

- FRACAS Data Analysis

- Software /Hardware Verification & Validation

Requirements & Interface Management Services

- Requirements Management Plan

- Requirements Management at Project/Contract level

- Interface Management-OEM/Vendor/Contractor

Reliability in Maintenance & Service Stage

- Product field life Estimation

- Reliability Centred Maintenance (RCM)

- FRACAS (Failure reporting, analysis, and corrective action system)

- Maintenance Analysis

- Product Performance Monitoring Index within Warranty Period

- Annual Maintenance Contract /Extended Warranty – Prediction for Cost to the Company

- Spare Part Analysis

- Customer Analytics

- Supply Chain Analytics

Reliability Goal setting & Project planning at Product and Subsystem level

- Supplier/Component selection and Validation

- DE rating Analysis and Reliability Prediction

- DFMEA/PFMEA

- Reliability Test Protocol Design & Execution

- HALT, ALT, RGT and Thermal Test

- Product & Subsystem Reliability assessments

- Field failure & Warranty analysis.

- FRACAS

- Reliability Certifications

- Reliability Standards – Prediction: MIL-HDBK-217Fn2, Telcordia SR 332 Issue 3, IEC 62380 (RDF), FMEA: IEC 60812 etc.

Safety & Risk Management Services

- Safety and Risk Management Plan

- Safety & Risk Analysis

- DFMEA

- PFMEA

- System/Subsystem Hazard Analysis

- Risk Estimation

- Risk Control : Development and Execution of Single Fault safety and Risk Management verification analysis Protocols and Reports.

Safety Certification

Standards: Safety Analysis: IEC 60601-1, • 80601-1 & sub clauses, PVHO-1-2007, AAMI / ANSI / IEC 60601-2-27:2011., Risk Management: IEC 60601-1, IEC 60601-2, ISO 13485, ISO 14971. etc.

Reliability in Concept & Feasibility Stage

- Safety Assurance Plan

- Preliminary Hazard Analysis (by conducting HAZID/HAZOP analysis)

- Set a Hazard Log (Live Hazard register to be updated regularly)

- System Reliability Project Planning

- Reliability requirements analysis

- Benchmarking

- Product Feasibility study

- Reliability Goal setting

- Reliability Engineering Training to Cross Functional Team

Reliability in Design & Development Stage

- System Reliability Block Diagram (RBD)

- Reliability Allocation

- Supplier selection & validation

- Component Stress vs. Strength and DE rating Analysis

- Reliability Prediction

- DFMEA and PFMEA

- Thermal Analysis

- Fault tree analysis (FTA)

- Design for X (DFX): assembly, testability, maintainability

Reliability Testing

- Reliability Test Planning

- Test Fixture Design & Development and Test Automation

- Highly Accelerated Life Test (HALT)

- Reliability Demonstration Test (RDT).

- Reliability Growth Test

- Accelerated Life Test (ALT)

- Single Fault Testing(SFT)

- Degradation (wear–to- failure) testing

- Environment Stress screening(ESS)

- Test Data analysis and Reliability Estimation

- Design verification

Reliability in Production Stage

- Highly Accelerated Stress Screening (HASS)

- Product Reliability acceptance test(PRAT)

- Development of Preventive Maintenance Plan

- Development of Spare Part Strategy Plan

- Warranty Cost Prediction

- Prediction of Cost to Company for different Warranty Policy

- Financial & Risk Analytics

Safety Assurance Services

- Safety Assurance Plan

- Preliminary Hazard Analysis (by conducting HAZID/HAZOP analysis)

- Set a Hazard Log (Live Hazard register to be updated regularly)

- Subsystem Hazard Analysis

- Interface Hazard Analysis

- Operations and Support Hazard Analysis

- FMECA, FTA, & SCIL Analysis

- Hazardous Material List

- Preliminary Design Safety Case

- Final Design Safety Case

- Final Safety Case

- Operating Instructions

- EMC Assurance Plan

- EMC Hazard Analysis, EMC Hazard Log

- System EMC Requirements

- EMC Demonstration Report

- EMC Safety Case

Training on RAMS & System Assurance

- Systems Assurance for Railway & Metro Systems

- CENELEC Std. EN 50126, EN 50128 and EN 50129

- Introduction to RAMS Parameters and associated Probability & Statistics

- System Reliability Modelling using Reliability Block Diagram

- Reliability Prediction using MIL-217 and NPRD

- Failure Mode Effects and Criticality Analysis

- Fault & Event Tree Analysis

- Design for Reliability, Apportionment of RAMS Parameters, Basics of V&V and Software Reliability

- Reliability Testing (HALT, ALT, RGT, HASS)

- Hazard Analysis & Risk Management

- SIL Allocation

- Safety Management System and Safety Certifications

- Reliability Centre Maintenance(RCM)